OSHA Inspection Checklist for Property Managers: 30-Point Audit

Property managers face a hidden liability: workplace safety violations. OSHA penalties start at $16,550 per serious violation, and a single workplace accident can trigger inspections uncovering dozens of violations.

Blocked exit routes. Missing fire extinguisher inspections. Unlabeled chemicals. Inadequate training. Each violation adds thousands in penalties.

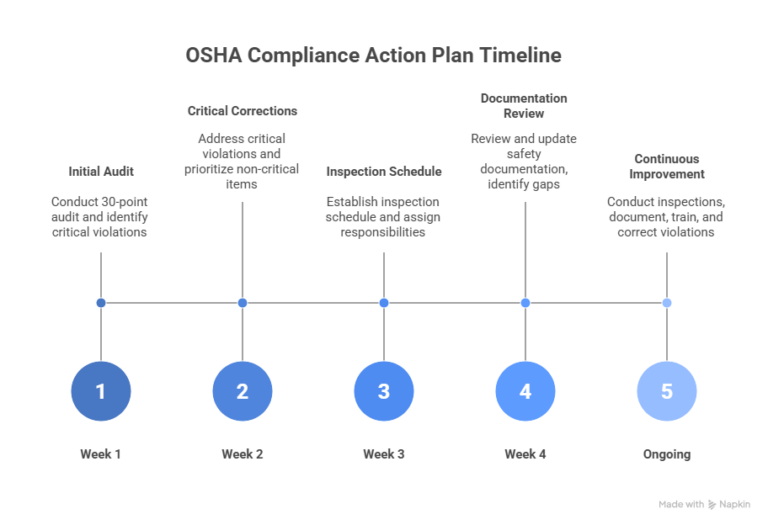

This OSHA inspection checklist for property managers provides a 30-point audit system to identify and fix violations before OSHA arrives.

Why Do Property Managers Need an OSHA Compliance Checklist?

OSHA doesn’t regulate properties; it regulates workplaces. When you employ maintenance staff, cleaning crews, leasing agents, or on-site workers, OSHA jurisdiction applies.

According to workplace safety data, there were 5,283 fatal workplace injuries in 2023. Property managers employing staff face the exact OSHA requirements as any other employer.

The General Duty Clause (Section 5(a)(1)) requires employers to provide workplaces free from recognized hazards likely to cause death or serious harm, even when no specific OSHA standard applies.

What Are the Most Common OSHA Violations in Property Management?

Understanding frequent violations helps you know where to focus inspection efforts. Based on OSHA enforcement data and real-world cases, these violations appear most often in property management:

- Exit route violations: Blocked exits, missing or non-illuminated exit signs, locked exit doors from the inside, inadequate emergency lighting. These violations are consistently among OSHA’s top citations across all industries.

- Fire safety deficiencies: Fire extinguishers missing, expired, or lacking monthly inspection tags. Sprinkler systems without current inspection certificates. Untested fire alarm systems. Missing documentation of fire drills for staff.

- Electrical hazards: Extension cords used as permanent wiring. Missing ground fault circuit interrupters (GFCIs) in wet locations like bathrooms and mechanical rooms. Uncovered electrical panels or panels blocked by storage. Damaged cords with exposed wiring.

- Hazard communication failures: Missing Safety Data Sheets (SDS) for cleaning chemicals, pesticides, and maintenance products. Unlabeled chemical containers when products are transferred from original packaging. No written hazard communication program. Lack of annual employee training on chemical hazards.

- Walking surface dangers: Wet floors without warning signs. Damaged or missing stair handrails. Loose carpeting or floor tiles creating trip hazards. Inadequate lighting in stairwells and common areas.

- Personal protective equipment (PPE) gaps: Failure to conduct hazard assessments to determine required PPE. Not providing appropriate safety equipment to employees at no cost. Missing training records for PPE use and maintenance.

Real consequences: Olivet Management, LLC in New York faced $2.35 million in initial penalties for 45 willful violations exposing workers to lead and asbestos without safety precautions. Sun Communities, Inc. received $6,000 in fines for inadequate PPE and chemical safety violations. These aren’t isolated cases; they represent systematic compliance failures.

How Should Property Managers Conduct Regular Safety Inspections?

Effective safety management requires scheduled inspections using a standardized checklist. Random walkthroughs miss critical items. Systematic audits catch violations before they become citations.

Inspection frequency recommendations:

- Monthly: Walking surfaces, exit routes, fire extinguishers, emergency lighting

- Quarterly: Electrical panels, HVAC systems, chemical storage areas, PPE inventory

- Annually: Complete 30-point audit, fire suppression systems, employee training review

Who should conduct inspections: Designate a safety coordinator, someone trained in OSHA requirements who understands your property operations. Commercial property managers typically assign this to facilities or operations managers. Residential property portfolios often use regional managers or maintenance supervisors.

Documentation is critical: Photograph hazards before and after correction. Date and sign off on each inspection. Store records for a minimum of three years (seven years recommended). This documentation proves due diligence during OSHA inspections and defends against citations.

Use inspection management software to track findings, assign corrective actions, and monitor completion. Digital records with timestamps and photos provide stronger evidence than paper checklists during audits.

What Does the Complete 30-Point OSHA Audit Checklist Include?

This comprehensive checklist covers the six major compliance categories property managers must monitor. Use it monthly for high-priority items and quarterly for complete property audits.

Emergency Preparedness & Fire Safety (Points 1-6)

- Emergency exits clearly marked and unobstructed – Exit signs illuminated, minimum 28-inch width maintained, no storage blocking egress paths.

- Exit doors unlock from inside – Push bars functional, doors swing outward in direction of travel, no chains or locks preventing interior exit.

- Emergency lighting is tested and operational – Battery backup systems tested monthly with documentation, lights provide adequate illumination for 90 minutes.

- Fire extinguishers accessible and inspected – Monthly visual checks documented with tags, annual professional servicing completed, proper type and rating for location.

- Fire alarm systems tested regularly – Quarterly testing documented, alarm audible throughout property, connection to monitoring service verified.

- Sprinkler systems inspected – Quarterly inspections by certified technicians, heads unobstructed by storage, valves accessible, and labeled.

Electrical Safety (Points 7-10)

- No damaged electrical cords or exposed wiring – All cords inspected for fraying, cracking, or exposed conductors; damaged items immediately replaced.

- GFCIs installed in wet locations – Ground fault protection present in bathrooms, kitchens, mechanical rooms, exterior outlets, and near water sources.

- Electrical panels properly maintained – All panels labeled with circuit directories, 36-inch clearance maintained, covers secured, no exposed live parts.

- Extension cords used temporarily only – No permanent use of extension cords as wiring; power strips not daisy-chained; proper gauge for load.

Walking & Working Surfaces (Points 11-14)

- Floors clean, dry, and hazard-free – Spills cleaned immediately, wet floor signs deployed, debris removed, uneven surfaces marked or repaired.

- Stairs equipped with secure handrails – Rails present on both sides where required, properly mounted, no loose connections, treads in good repair.

- Carpets and floor coverings secured – No tears, lifted edges, or wrinkles; transitions between surfaces secured; mats have beveled edges.

- Adequate lighting throughout property – Minimum illumination levels met per OSHA standards, burned-out bulbs replaced promptly, emergency pathways well-lit.

Hazard Communication & Chemical Safety (Points 15-18)

- Safety Data Sheets accessible – Current SDS maintained for all hazardous chemicals on property, organized in binder or digital system, available to employees 24/7.

- Chemical containers properly labeled – All containers show contents and hazard warnings, secondary containers labeled when chemicals are transferred from original packaging.

- Written Hazard Communication Program on file – OSHA-compliant program documents chemical inventory, labeling procedures, SDS management, employee training.

- Employees trained on chemical hazards – Annual training documented with dates and topics, training includes proper handling, emergency response, and PPE requirements.

Personal Protective Equipment (Points 19-21)

- Workplace hazard assessment documented – Written assessment identifies all hazards requiring PPE, updated when conditions change, or new hazards are identified.

- Appropriate PPE provided at no cost – Safety glasses, gloves, hearing protection, respirators (when needed) provided based on hazard assessment.

- PPE training completed and documented – Employees trained on selection, proper use, maintenance, and limitations of PPE; training records maintained.

Mechanical Systems & Maintenance (Points 22-24)

- Mechanical rooms organized and ventilated – Adequate airflow for equipment, clear access to all systems, no storage blocking equipment or exits.

- Machinery equipped with guards and safety devices – All moving parts properly guarded, emergency stops functional, safety interlocks operational.

- Lockout/Tagout procedures established – Written procedures for energy isolation during maintenance, locks and tags available, employees trained on LOTO requirements

Documentation & Training (Points 25-30)

- OSHA posters displayed – “Job Safety and Health: It’s the Law” poster visible in employee common areas, contact information current.

- Injury/illness records maintained – OSHA 300 Log current if 10+ employees, Form 300A posted February 1–April 30, records retained for five years.

- Employee training records current – All safety training documented with employee names, dates, topics covered, and trainer signatures.

- Inspection and maintenance records organized – Fire extinguisher tags, sprinkler certificates, electrical inspections, HVAC service records readily accessible.

- Emergency action plan documented – Written plan required if 10+ employees, includes evacuation procedures, emergency contacts, and employee responsibilities.

- First aid kits stocked and inspected – Kits accessible, contents adequate for employee count, inspection logs current, expired items replaced.

How Can Technology Simplify OSHA Compliance Tracking?

Manual compliance management through paper checklists and spreadsheets doesn’t scale beyond a few properties. Property management platforms with integrated compliance tracking transform OSHA management from reactive to proactive.

- Automated inspection scheduling triggers monthly, quarterly, and annual audits automatically. Assigned team members receive reminders 30, 14, and 7 days before inspections are due. No more missed deadlines or forgotten safety checks.

- Digital document management centralizes all compliance records, training certificates, inspection reports, contractor licenses, and equipment certifications in searchable, cloud-based storage. When OSHA requests documentation during an inspection, you retrieve it in seconds instead of digging through filing cabinets.

- Photo documentation embeds directly into inspection reports. Before and after photos of corrected hazards, timestamped and geotagged, provide powerful evidence of due diligence.

- Task assignment and tracking ensures accountability. When inspections identify violations, assign corrections to specific team members with deadlines and completion verification. Management sees exactly what’s complete and what’s overdue across entire portfolios.

- Compliance dashboards show your safety status at a glance: upcoming inspections, overdue items, training expiration dates, and certificate renewals. Red flags appear before they become violations.

For property managers overseeing multiple property types, centralized compliance tracking becomes essential. Different properties have different OSHA requirements. Commercial buildings face stricter ADA obligations than residential properties. Software manages these variations automatically.

What Should Property Managers Do When OSHA Shows Up?

OSHA inspections happen. Knowing the process protects your interests.

- Verify credentials – Request official OSHA ID with photo and serial number.

- Determine scope – Understand why they’re there: complaint, accident, programmed inspection, or referral.

- Designate a representative – Accompany the inspector. Choose your safety coordinator or facilities manager.

- Document everything – Take notes and photos of what the inspector examines.

- Provide requested documents – Training records, injury logs, safety programs, inspection records ready for immediate access.

- Attend the closing conference – Inspectors explain findings. Ask questions and explain corrective actions underway.

- Review citations carefully – You have 15 working days to contest. Begin abatement immediately regardless.

According to Liberty Mutual’s research, workplace injuries average $40,000 per incident. OSHA penalties are just the beginning.

What Are the Best Practices Beyond the Checklist?

Compliance requires building a safety culture that protects employees and your business.

- Establish a safety committee with departmental representatives. Monthly meetings review incidents, discuss near-misses, and identify emerging hazards.

- Conduct quarterly safety training – toolbox talks on ladder safety, chemical handling, and heat stress keep safety top-of-mind. Document all training.

- Manage contractors carefully – require insurance proof, written safety programs, and licenses before work begins. Conduct pre-work safety orientations and verify proper LOTO procedures.

- Implement preventive maintenance – regular servicing and inspections prevent hazardous conditions from developing.

- Investigate all incidents – document what happened, identify root causes, implement corrections, and share learnings across your portfolio.

Property managers who integrate safety management into operations rather than treating it as an administrative burden see fewer accidents, lower insurance costs, better employee retention, and virtually no OSHA citations.

Your 30-point OSHA inspection checklist for property managers provides the framework. Consistent execution provides the protection.

Contact Propertese today to centralize your safety compliance tracking and automate inspection management.